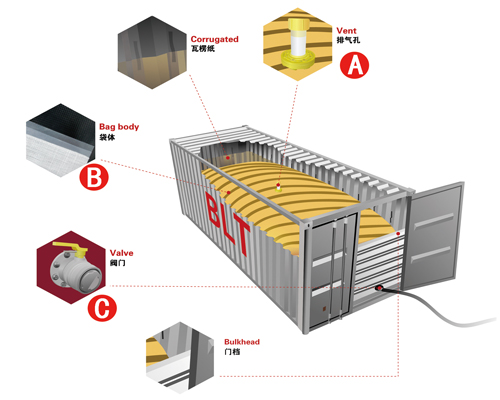

Automatic Air Vent Valve

Protective Outer Layer Upgrade

Our engineers tracked and tested 1000 flexitanks under different transportation modes and conditions. We made BLT flexitanks reflect the highest standards.

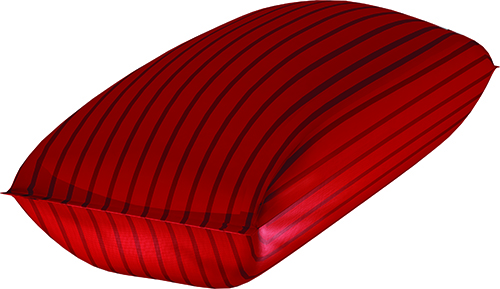

a) The protective outer layer of flexitank is made of high-technical aramid fibers, which possesses an incomparable advantage for tension and softness against ordinary PP fiber.

b) A high strength zonal reinforcing rib which reflects an innovative upgrade in the safety area of flexitank is applied between each 10cm of the protective layer.

c) The protective outer layer of flexitank is a 4-meter-wide single time integral molding bag which is safer and more reliable in comparison with traditional fission suture of PP protective bag.

With this technical innovation, flexitank always performs well under normal conditions.

3-inch Ball Valve

Compare with butterfly valve, 3-inch ball valve seals tighter and has better resistance to pressure. Since the 3-inch ball valve has no block when it is opened, it makes liquid flow through freely and quickly.

In the joint position between the internal valve and flexitank, a safety protection device, which effectively prevents inner film layer from blocking the valve, is added, thus the residual liquid will reduce to a minimum after discharging.

Our technical team is continuously exploring the application and usage of flexitank. We have successfully developed the flexitank for loading high-temperature liquid at 150 degrees Celsius and the high barrier flexitank for the liquid which is sensitive to oxygen. In addition, we are willing to customize the products for our users.